You're looking at an outdated version of our homepage!

Please visit the new web page: www.genser.de

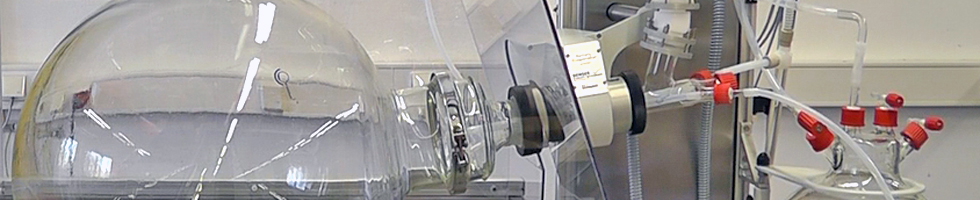

PILOTVAP

Rotary Evaporator

PILOTVAP®

The PILOTVAP® is a patented pendulum system rotary evaporator.

Technical Details of the PILOTVAP®

Controller

GUARD (standard)

- Manual or automatic vacuum control

- Control of the aerating valve (air- or nitrogen inlet)

- Vapor temperature control

- Speed control with slow acceleration mode

- Control of the water bath temperature

GUARD SCU (option)

- Speed control with slow acceleration mode

- Control of the water bath temperature (option)

- Vapor temperature control (option)

Rotating flask

- The floating rotating flask reduces mechanical stresses, to achieve constant tightness and a powerful distillation result, even under permanent operation.

- Hydraulic damping system for the rotating flask with drive system (patented), to increase the performance, when drying powders.

- Surface treated glass flanges for maximal vacuum stability.

Sealing system

- High performance sealing system

- PTFE / glass

- Service life approx. 20,000 hours of operation

- Final vacuum better than 0.1 hPa (when empty)

- 3 years warranty - Sealing system STACONSEAL, patented (option)

- Final vacuum better than 0.01 hPa (when empty) - By means of the novel sealing system, a very good solvent recovery rate will be achieved

Protection Systems

- Vapor temperature alarm, to automatically shut off the water bath.

- Implosion protection hood for the rotating flask, made of transparent polycarbonate.

- The pendulum system makes the rotating flask float in the water bath, to guarantee highest performance, easy handling and maximal reliability.

Ex-proof pilotvap-system

PILOTVAP®-Applications

- Excellent suitable for recovery of solvents

- Problem-free distillation of high boiling solvents

- Distillation of large amounts of solvent

- Concentration of extracts

- Drying of powders

- Concentration of fractions coming from HPLC

Hint

All PILOTVAP®-Systems can be modified to the

fully automated rotary evaporator POWERVAP®.